A4 copier paper manufacturing machinery

Key words:

paper machinery

Share

Product Details

Technical Parameters

| Raw Materials | Pulp Waste Paper |

| Output Paper | Copy Paper, Printing Paper |

| Output Paper Weight | 60-80g/m2 |

| Net Paper Width | 1800mm |

| Capacity | 15T/D |

| Working Speed | 30 m/min |

| Design Working Speed | 80 m/min |

| Wiring Width | 3150mm |

| Gauge | 3600mm |

| Lane | AC frequency conversion speed regulation, segmented drive |

Host

| Using the above recycled fiber materials can save: | |

| Energy | Making paper from recycled materials (waste paper) consumes 64% less energy than making paper from virgin fibers (trees). Recycling one ton of paper saves the equivalent of 70 gallons of gasoline or 3 barrels of oil. |

| Water | Using 100% recycled materials to make paper reduces water consumption by 61%. |

| Land | For every ton of recycled paper, 100 cubic feet of landfill space is saved. |

| Air | Compared to making paper from virgin wood, air pollutants are reduced by 70% in the production of recycled paper. |

| Natural Resources (Trees) | For every ton of recycled paper, approximately 17 trees are saved. |

1. Waste paper and pulp (lower cost, ideal choice)

2. Wood, straw, cotton, bagasse, bamboo, etc. (higher cost than wood pulp and waste paper)

Pulp production lines using different raw materials will have different structures. Therefore, please specify in Your Requests. Then we will recommend suitable machines to you at a reasonable Price.

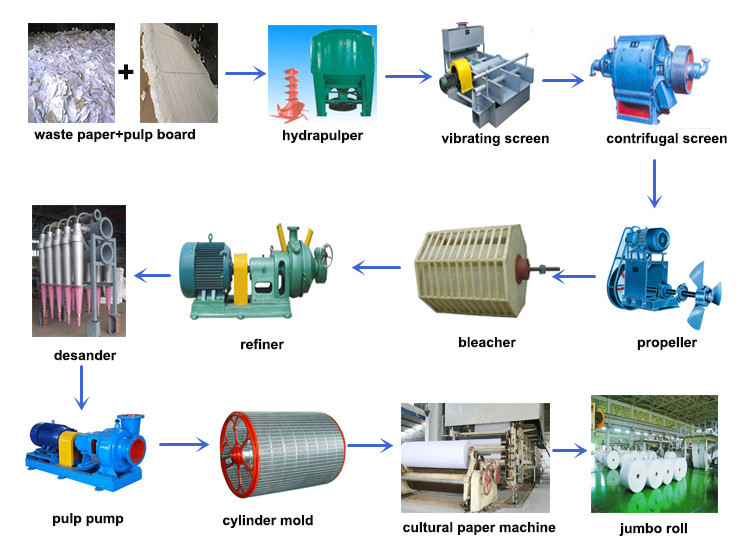

Ordinary waste paper pulp, wood pulp process:

After unpacking waste paper and wood pulp boards, removing the wire, they are transported by a plate conveyor to a hydraulic pulper for crushing. The hydraulic pulper is used for pulping and de-inking, and the pulped pulp is formed into pulp.

⇓

The pulp is pumped into a high-frequency vibrating screen, which plays the role of screening and separating impurities; after the pulp in the pulp enters the pulp

⇓

The pulp is pumped into a thickener, which mainly reduces the consistency of the pulp. Through concentration and improvement, concentration can also achieve the purpose of washing the pulp; the concentrated pulp flows into the pulp pool.

⇓

The pulp is pumped into a bleaching machine, whose function is to clean and bleach the pulp; the bleached pulp enters the pulp pool.

⇓

The pulp is pumped into a grinder to grind it into pulp, which automatically flows into the pulp pool.

⇓

The pulp is pumped into a sedimentation tank, and after sedimentation, impurities such as sand and ash are separated, and pure pulp is precipitated.

⇓

The pulp is pumped into a pressure tank, which regulates the pulp consistency.

⇓

After passing through the pressure tank, the impurities in the pulp are removed, the impurities in the sand particles are removed again, the pulp enters the flat box, and is mixed to form pure pulp.

As shown in the flow chart, a4a3 paper conversion production line:

1. a4-a3 large roll → slitting machine → a4 Size cutting machine → a4-a3 paper → automatic packaging machine → finished product

2. a4-a3 large roll → rewinding and slitting machine → automatic a4-a3 paper-making machine → automatic packaging machine → finished product

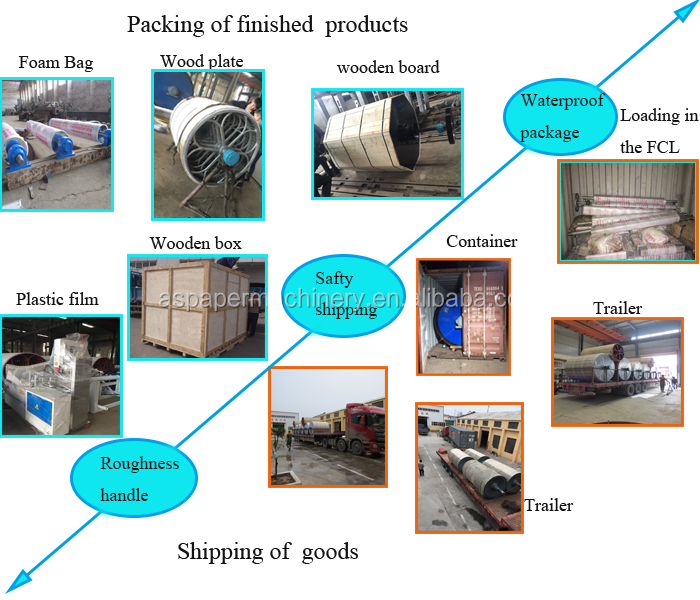

Packaging and Transportation

| Packaging a4 copy paper making machinery | a4 copy paper making machinery output |

| 1. Secure all moving parts with plastic film. | 1. Sea freight from Qingdao seaport or other ports. |

| 2. Wrapped with polystyrene foam board. | 2. Delivery time depends on the machine or machine parts you need. But it also meets your needs. |

| 3. Wrap several times with tight plastic film. | |

| 4. Secure the machine to the fumigated plywood pallet with wire. | |

| 5. Wrap with wooden boards and nail them. |

Advantages

2400mm type waste paper recycling machine produces a4 copy paper making machinery

| Business Scope | 1. Various pulpers; |

| 2. Various paper machines; | |

| 3. Various paper processing machines; | |

| 4. Various spare parts; | |

| Technical Strength | A professional technical team consisting of 108 engineers and 12 experts; |

| 2. 31 years of rich practical experience; | |

| 3. An innovative research team, always following the advanced technology of Finland, Denmark and Italy; | |

| 4. Skilled and meticulous workers; | |

| Our market | Our machines are sold well in more than 30 countries and regions, including Russia, Indonesia, Uzbekistan, Tajikistan, Nigeria, Uganda, Pakistan, Egypt, Bhutan, Fiji, Brazil, Paraguay, Syria, Libya, Turkey, and Canada. High quality and perfect service have won customers' praise and more orders. We have also established good strategic partnerships with local distributors. |

Company Information

Qinyang Anshun Paper Machinery Co., Ltd.

Located in Jiaozuo City, Henan Province, with convenient transportation and over 25 years of experience.

We focus on the research and development of papermaking machinery.

Our company envisions a market with widespread sales in Africa, Europe, South Africa, and Asia.

Our company has introduced a series of advanced equipment, including toilet paper machines, kraft paper machines, cultural paper machines, and corrugated paper machines.

We also welcome OEM and ODM orders.

Whether selecting current products from our catalog or seeking engineering assistance for your application.

Main Markets

Warm Tips:

1. Before installation, check whether the Model and Size of the equipment are correct, whether the parts are complete, and whether the level is maintained.

2. Before the installation test, check whether each component is correct and whether the lubricating oil supply is normal. Whether the water and electricity values meet the standards.

3. During operation, pay attention to daily inspection, cleaning, and refueling, and then conduct regular inspections and maintenance.

Advantages

Customer-centered design principles

High yield, high quality

Proven skills and technical support

Thoughtful pre-sale and after-sale service

Appropriate discounts can be negotiated

Packaging, transportation and delivery

Packaging Details: According to customer's request for the price of paper recycling machine

1. Fix all moving parts with plastic film.

2. Polystyrene foam board package.

3. Wrap a few circles with tight plastic film.

4. Fix the machine on the fumigated plywood tray with iron wire.

5. Wrap it with wood and nail it.

Transportation

Mode of transport

Departure from Qingdao harbor or other ports

Delivery time

Depends on the machine or machine parts you need. But it also meets your needs

OUR SERVICES

After-sales service

(a) technical advice;

2. Project evaluation;

3. Detailed factory design;

4. Installation and testing of the entire production line;

Training of engineers and workers;

6. Provide spare parts for the entire service life at cost price within 12 months of purchase.

7. We support sending engineers to your country for the installation, commissioning and testing of the machine.

After-sales service

1. The company designs and manufactures in strict accordance with the signed equipment configuration and technical requirements, in accordance with national industry standards, and ensures that the user's equipment is a qualified product that meets the requirements.

2. After the contract comes into effect, within ten days after the equipment design and manufacturing company and the end user coordinate, link up and check the installation process; The business dealings between the two parties must be replied within 8 hours.

3. The equipment shall be installed and debugged according to the time and period agreed by both parties.

4. The quality and shelf life of the equipment are one year, and the wearing parts are not within the warranty period. Packaging quality drum shelf life of six months. Refers to the acceptance date of all goods delivered to the user as the shelf life.

5, in the quality warranty period, the company provides the necessary technical services free of charge, due to equipment design, manufacturing quality problems caused by equipment

The company will be responsible for replacement and maintenance.

6. After the shelf life, the company provides customers with lifelong technical services, and provides spare parts at preferential prices and fast delivery time for a long time.

7, the company is responsible for all production technology and installation, awarded to production workers, to ensure that the teaching workers operate.

FAQ

Q

Can we visit your factory?

A

Welcome to visit our factory. You can view our production capacity, processing capacity, inspection facilities, and operation of paper production lines. More importantly, you can directly discuss with the engineer.

Q

How is the quality of your equipment?

A

(1) We are a professional manufacturer of various pulp and paper machines and environmental protection equipment, with a history of more than 40 years and competitive quality.

(2) We have a technical team composed of engineers and experts. They mainly research advanced papermaking technology to ensure that our machine design is up-to-date.

(3) The machine will be pre installed in the workshop before delivery.

Q

What is the warranty period for paper machines?

A

12 months after official operation

recommend products

Product Consulting

Note: Please leave your contact information and our professionals will contact you as soon as possible!