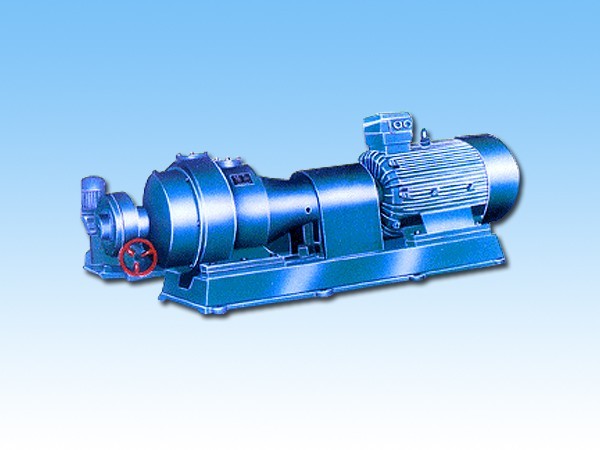

Pump machine used for pulping part of tissue toilet paper pulp making

Key words:

paper machinery

Share

Product Details

Introduction of paper pulper machine

1.China supplier patented paper machine hydrapulper price adopts D type structure, which improves work efficiency.

2. It can be used for pulping waste paper & wet strengh paper.

3. D-Type Hydrapulper is mainly used to crushing pulp board, waste paper, deinking, and pulp purification.

4.Through dissociating, it can maximum make the paper’s fiber dissociating into fiber bundles or single fibers, while at the same time, it can maximize maintain impurity’s shape and strength.

STRUCTURE

This paper pulp machine consists of tank, pulper rotor, landing leg, driving device and motor.

Main Features

1.Pulper rotor off-center position so that the waste paper could touch the rotor more quick and higher frequency.

2.The tank is made by welded steel,outside of mouth is ultra high strength steel,which used to strengthen tank,in the bottom of cone have deflector,which can make the paper pulp reflux circulating.In the bottom of tank is impurity discharge outlet.

3.Pulper rotor and pulp tray is higher than pulper groove bottom plane,which can reduce the pulper rotor and impurities contact,so that prolong life-span,preventing the twisted rope winding on the rotor.

Advantages

This machine can promptly crushing waste paper with large capacity,low power consumption,and saving vapour medication.And it is easy to maintain with long service life,low noise,and the vibration is not strong.In stable operation,it also can save energy.

Packaging&Shipping

Packaging&Shipping:the standards packing for shipment with 40feet GP,40 feet OT or 40 feet FR.Cylinder mould and press roll,couch roll,felt rolls are packed with wooden pakage.

Advantages

Customer-centered design principles

High yield, high quality

Proven skills and technical support

Thoughtful pre-sale and after-sale service

Appropriate discounts can be negotiated

Packaging, transportation and delivery

Packaging Details: According to customer's request for the price of paper recycling machine

1. Fix all moving parts with plastic film.

2. Polystyrene foam board package.

3. Wrap a few circles with tight plastic film.

4. Fix the machine on the fumigated plywood tray with iron wire.

5. Wrap it with wood and nail it.

Transportation

Mode of transport

Departure from Qingdao harbor or other ports

Delivery time

Depends on the machine or machine parts you need. But it also meets your needs

OUR SERVICES

After-sales service

(a) technical advice;

2. Project evaluation;

3. Detailed factory design;

4. Installation and testing of the entire production line;

Training of engineers and workers;

6. Provide spare parts for the entire service life at cost price within 12 months of purchase.

7. We support sending engineers to your country for the installation, commissioning and testing of the machine.

After-sales service

1. The company designs and manufactures in strict accordance with the signed equipment configuration and technical requirements, in accordance with national industry standards, and ensures that the user's equipment is a qualified product that meets the requirements.

2. After the contract comes into effect, within ten days after the equipment design and manufacturing company and the end user coordinate, link up and check the installation process; The business dealings between the two parties must be replied within 8 hours.

3. The equipment shall be installed and debugged according to the time and period agreed by both parties.

4. The quality and shelf life of the equipment are one year, and the wearing parts are not within the warranty period. Packaging quality drum shelf life of six months. Refers to the acceptance date of all goods delivered to the user as the shelf life.

5, in the quality warranty period, the company provides the necessary technical services free of charge, due to equipment design, manufacturing quality problems caused by equipment

The company will be responsible for replacement and maintenance.

6. After the shelf life, the company provides customers with lifelong technical services, and provides spare parts at preferential prices and fast delivery time for a long time.

7, the company is responsible for all production technology and installation, awarded to production workers, to ensure that the teaching workers operate.

FAQ

Q

Can we visit your factory?

A

Welcome to visit our factory. You can view our production capacity, processing capacity, inspection facilities, and operation of paper production lines. More importantly, you can directly discuss with the engineer.

Q

How is the quality of your equipment?

A

(1) We are a professional manufacturer of various pulp and paper machines and environmental protection equipment, with a history of more than 40 years and competitive quality.

(2) We have a technical team composed of engineers and experts. They mainly research advanced papermaking technology to ensure that our machine design is up-to-date.

(3) The machine will be pre installed in the workshop before delivery.

Q

What is the warranty period for paper machines?

A

12 months after official operation

recommend products

Product Consulting

Note: Please leave your contact information and our professionals will contact you as soon as possible!