Kraft paper waste scrap recycling machines

Key words:

paper machinery

Share

Product Details

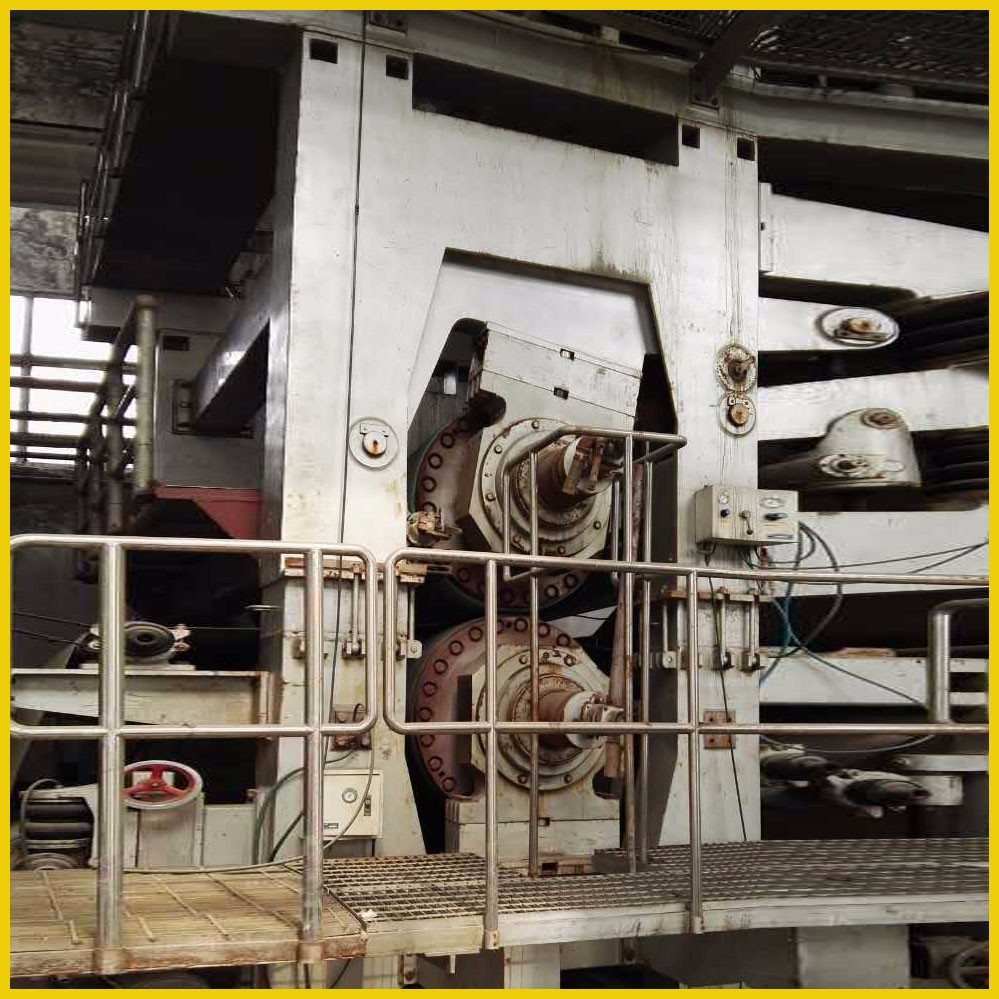

Pictures show of kraft paper waste scrap recycling machines

This model of Kraft paper making machine with engineers overseas work is a medium scale machine.The main structures of it including wire part,dryer part and winding part.

Details show are as followed.(Photos below are taken from our clients who bought our machines.)

Technical parameter of kraft paper waste scrap recycling machines

1.Raw material:Waste Paper,used Corrugation Box

2.Output paper:liner paper,corrugated paper,kraft paper,white craft liner paper

3.Output weight:100-150GSM

4.Net paper width:1880mm

5.Wire width:2300mm

6.Rail guage:2800mm

7.Design speed:150m/min

8.Work speed:100-130m/min

9.Capacity:30T/D

10.Pressure type:pneumatic pressure device

11.Driving type:use AC frequency conversion,and driving by step

12.Pulp formation type:pressure mould former

Features of kraft paper waste scrap recycling machines

-----Controlling way

Adopt Siemens or Sanken inverter and high quality low voltage apparatus.

-----The main core hardware supporting

Every branch transmission point goes with a AC Inverter,indicator lamp,air switch,terminal board and so on;these all sino-foreigh joint products.

-----Transmiss control cabinet

All adopt standard GGD control cabinet,including power supply cabinet,transmission cabinet.

-----Operational panel

Including main transmission operational panel.

Main frame of kraft paper waste scrap recycling machines

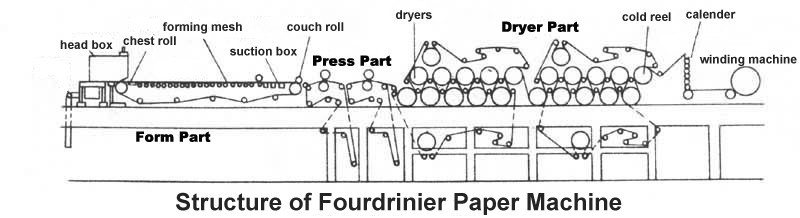

For Kraft liner corrugated paper producing,there are several different paper machine types for you to choose,such as cylinder type,fourdrinier type,inverformer type,etc.Actually,most economic one is cylinder type but its stablity is lower than other two types.Here I take fourdrinier type for an example for your reference.

1.Form part: long wire with suction box for paper forming

2.Press part: nature marble roll 2 sets,rubber roll 2 sets,,Pneumatic pressure device.

3.Dryer part: alloy dryer can18 sets,with dryer screen device.with 18 blades,with semi-closed exhaust hood 1 group

4.winding part: 2400mm winding machine 1 set

5.Rewinding part:2400mm rewinding machine 1 set

Flowchart of kraft paper waste scrap recycling machines

Take waste paper as raw material,flowchart is as followed.In addition,if you want to produce liner paper,you need to use different and seperate equipment to make top pulp and bottom pulp.

Raw materials of kraft paper waste scrap recycling machines

A varity of raw materials can be used to produce Kraft liner paper and fluting paper,such as waste paper,recycled cartons,rice or wheat straw,wood pulp,etc.However,if you want to produce high quality Kraft liner paper,wood pulp will be your best choose.If you have cost controls on raw materials stocking,tell us plz and we will provide you most competitive solution.

Final products of kraft paper waste scrap recycling machines

Equipment List-Pulping equipment

| NO. | Equipment | Quantity(set/sets) |

| 1 | 15m³ high consistency hydrapulper | 1 |

| 2 | φ450 double disk refiner | 3 |

| 3 | 2m²pressure screen | 1 |

| 4 | 606 disander(12sets) | 4 groups |

| 5 | φ700 thruster | 8 |

| 6 | 8 inch pulp pump | 4 |

| 7 | 6 inch pulp pump | 6 |

| 8 | 6 inch water pump | 2 |

| 9 | rewinding& perforated machine | 1 |

| 10 | cutter | 1 |

Packaging & Shipping

Why choose us

Part 1:

1)Low MOQ: It can meet your low qty demand very well.

2)Good Service: We treat clients business as our own business.

3)Good Quality:We have strict QC quality control system .Good reputation in the market.

4)Fast & Cheap Delivery: We have big discount from shipping forwarder (Long Contract).

Part 2:

1. We have rich experience in this industy(our company was established in 1996);

2. We are the factory outlet ,can give you a cheaper price ;

3. For the machine,we have complete paper machinery with top quality.

Company Gallery

Products from us can be devided into three types.

1.The first type is paper making machine,which is the main part to produce different kinds of paper,like toilet tissue paper,cultural paper,newsprinting paper,fluting corrugated paper,coating paper and Kraft paper.

2.The second part is paper processing machines,which can be used for transfering big jumbo rolls into final products.For example,we provide napkin folding machine by which you can produce napkin paper.

3.The third type is pulp making equipment,which is vital for paper making.As we know,paper pulp is basic for real paper,that's why pulp equipment is so important.We produce all kinds of pulp making equipment,such as hydrypulper,vibrating screen,high-speedwasher,bleacher,pressure screen,refiner,desander and so on,which can improve the pulp inpurity and then ensure you produce pulp with best quality.

Contact Us

Advantages

Customer-centered design principles

High yield, high quality

Proven skills and technical support

Thoughtful pre-sale and after-sale service

Appropriate discounts can be negotiated

Packaging, transportation and delivery

Packaging Details: According to customer's request for the price of paper recycling machine

1. Fix all moving parts with plastic film.

2. Polystyrene foam board package.

3. Wrap a few circles with tight plastic film.

4. Fix the machine on the fumigated plywood tray with iron wire.

5. Wrap it with wood and nail it.

Transportation

Mode of transport

Departure from Qingdao harbor or other ports

Delivery time

Depends on the machine or machine parts you need. But it also meets your needs

OUR SERVICES

After-sales service

(a) technical advice;

2. Project evaluation;

3. Detailed factory design;

4. Installation and testing of the entire production line;

Training of engineers and workers;

6. Provide spare parts for the entire service life at cost price within 12 months of purchase.

7. We support sending engineers to your country for the installation, commissioning and testing of the machine.

After-sales service

1. The company designs and manufactures in strict accordance with the signed equipment configuration and technical requirements, in accordance with national industry standards, and ensures that the user's equipment is a qualified product that meets the requirements.

2. After the contract comes into effect, within ten days after the equipment design and manufacturing company and the end user coordinate, link up and check the installation process; The business dealings between the two parties must be replied within 8 hours.

3. The equipment shall be installed and debugged according to the time and period agreed by both parties.

4. The quality and shelf life of the equipment are one year, and the wearing parts are not within the warranty period. Packaging quality drum shelf life of six months. Refers to the acceptance date of all goods delivered to the user as the shelf life.

5, in the quality warranty period, the company provides the necessary technical services free of charge, due to equipment design, manufacturing quality problems caused by equipment

The company will be responsible for replacement and maintenance.

6. After the shelf life, the company provides customers with lifelong technical services, and provides spare parts at preferential prices and fast delivery time for a long time.

7, the company is responsible for all production technology and installation, awarded to production workers, to ensure that the teaching workers operate.

FAQ

Q

Can we visit your factory?

A

Welcome to visit our factory. You can view our production capacity, processing capacity, inspection facilities, and operation of paper production lines. More importantly, you can directly discuss with the engineer.

Q

How is the quality of your equipment?

A

(1) We are a professional manufacturer of various pulp and paper machines and environmental protection equipment, with a history of more than 40 years and competitive quality.

(2) We have a technical team composed of engineers and experts. They mainly research advanced papermaking technology to ensure that our machine design is up-to-date.

(3) The machine will be pre installed in the workshop before delivery.

Q

What is the warranty period for paper machines?

A

12 months after official operation

recommend products

Product Consulting

Note: Please leave your contact information and our professionals will contact you as soon as possible!