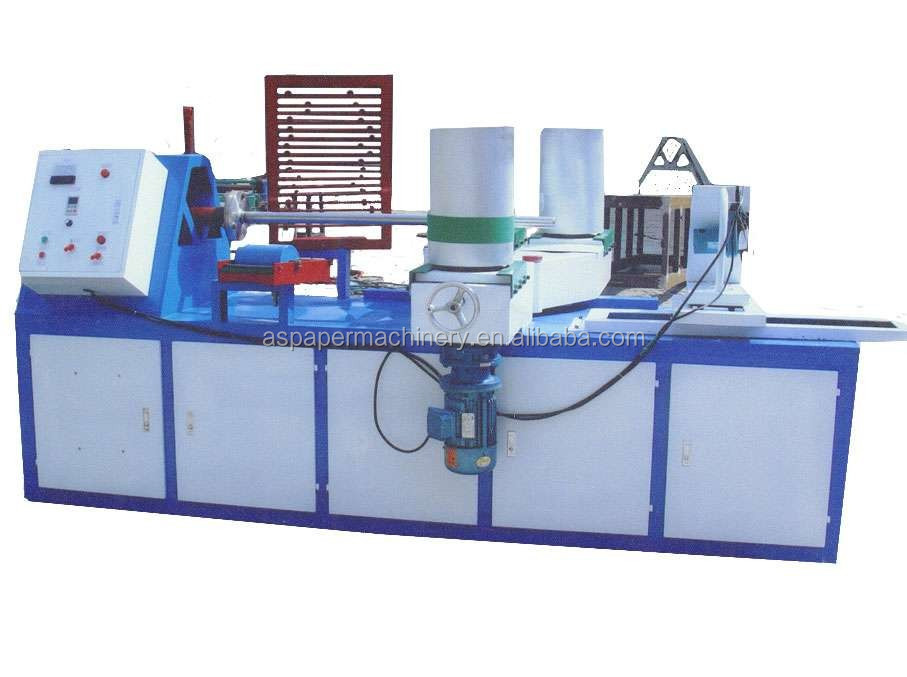

Paper core tube manufacturing machine

Key words:

paper machinery

Share

Product Details

Paper tube machine (paper tuber equipment), is the production of paper machines and equipment, the production of paper tubes used in various industries, chemical industrial pipe, used in the film industry tubes, tubes for use in the printing industry, paper industry tubes, tubes for use in the leather industry, food packaging tubes, tubes for use in the construction industry, exhibition industry ect.

Features:

1.automatic cutting drop tube, out of paper to break the automatic stop function;

2.cutting speed automatically when auto reply;

3.computer PLC control with remote control port;

4.multipoint operation panel or digital remote control, operation is very convenient;

5.circle cutter active cut, cut more smoothly, more stable;

6.more than 80 feature set, any set the machine in motion;

7.stainless steel plastic pots, poly-resin glue, high carbon steel glue. durable;

8.automatic glue.

Technical Parameter |

Control system |

||

Number of roller |

3-16 layer |

PLC controller |

Delta |

Tube diameter |

25-200 mm |

Touch screen |

MCGS |

Tube wall-thickness |

1-10 mm |

Transducer |

MITSUBISHI |

Core mould fixed way |

Flank chuck |

Electric part |

Schneider |

Winding head |

4 |

Single part |

Omron |

Cutting way |

Round knife |

Pneumatic part |

AIRTAC |

Gluing way |

Single / double sides |

Fix length way |

Optoelectronic switch/encode |

Operator |

1-2 person |

Equip device |

|

Winding speed |

3-30 m/min |

Paper shelf type |

Integral reel stand |

Speed control |

Transducer |

Auto fall tube shelf |

Have |

Driving system |

Glue shelf |

Have |

|

Main motor |

7.5 KW |

Belts |

4 |

Reducer type |

WPO155 |

Core mould |

2 |

Mainframe size & Weight |

|||

Mainframe size |

5200*2000*2000 mm |

Weight |

3000 KG |

Area space |

14000*60000 mm |

||

Products show

Operational manual

1.the right to wear personal protective equipment.The dress must be worn,and should not be worn must not wear.For example when the paper tube machine requires workers to wear helmet,if you do not wear may twist their hair into it.Also requested not to wear gloves if you wear,paper tube glove mechanical rotating parts may be twisted,twisted hand injury.

2.paper tubes during the operation of machinery and equipment according to the provisions for security checks.Especially for fastening objects to see if loose due to vibrations,so that the fastening.

3.security checks prior to operation of paper machinery and equipment,but also to open drive,verify that normal,may be put into operation.

4.equipment prohibited operation,do not make use,in case of an accident.

5.paper machines in operation,no hand adjustment or measuring parts by hand,or lubrication,cleaning and other debris.Must be an ongoing,you should first shut down machinery and equipment.

6.paper machinery and equipment using tools,fixtures,and machined parts must be installed firmly,not loose.

7.mechanical safety device must be used according to regulations,must not be removed is not in use.

8.paper machinery and equipment operation,operator shall not leave jobs in case no disposal if a problem occurs.

9.after work,switch should be closed,exit from the working position the tool and workpiece,and clean up the work site,spare parts,tools and fixtures placed in order,clean good paper machinery health

workshop corner

Packing & Delivery

More type machine

Advantages

Customer-centered design principles

High yield, high quality

Proven skills and technical support

Thoughtful pre-sale and after-sale service

Appropriate discounts can be negotiated

Packaging, transportation and delivery

Packaging Details: According to customer's request for the price of paper recycling machine

1. Fix all moving parts with plastic film.

2. Polystyrene foam board package.

3. Wrap a few circles with tight plastic film.

4. Fix the machine on the fumigated plywood tray with iron wire.

5. Wrap it with wood and nail it.

Transportation

Mode of transport

Departure from Qingdao harbor or other ports

Delivery time

Depends on the machine or machine parts you need. But it also meets your needs

OUR SERVICES

After-sales service

(a) technical advice;

2. Project evaluation;

3. Detailed factory design;

4. Installation and testing of the entire production line;

Training of engineers and workers;

6. Provide spare parts for the entire service life at cost price within 12 months of purchase.

7. We support sending engineers to your country for the installation, commissioning and testing of the machine.

After-sales service

1. The company designs and manufactures in strict accordance with the signed equipment configuration and technical requirements, in accordance with national industry standards, and ensures that the user's equipment is a qualified product that meets the requirements.

2. After the contract comes into effect, within ten days after the equipment design and manufacturing company and the end user coordinate, link up and check the installation process; The business dealings between the two parties must be replied within 8 hours.

3. The equipment shall be installed and debugged according to the time and period agreed by both parties.

4. The quality and shelf life of the equipment are one year, and the wearing parts are not within the warranty period. Packaging quality drum shelf life of six months. Refers to the acceptance date of all goods delivered to the user as the shelf life.

5, in the quality warranty period, the company provides the necessary technical services free of charge, due to equipment design, manufacturing quality problems caused by equipment

The company will be responsible for replacement and maintenance.

6. After the shelf life, the company provides customers with lifelong technical services, and provides spare parts at preferential prices and fast delivery time for a long time.

7, the company is responsible for all production technology and installation, awarded to production workers, to ensure that the teaching workers operate.

FAQ

Q

Can we visit your factory?

A

Welcome to visit our factory. You can view our production capacity, processing capacity, inspection facilities, and operation of paper production lines. More importantly, you can directly discuss with the engineer.

Q

How is the quality of your equipment?

A

(1) We are a professional manufacturer of various pulp and paper machines and environmental protection equipment, with a history of more than 40 years and competitive quality.

(2) We have a technical team composed of engineers and experts. They mainly research advanced papermaking technology to ensure that our machine design is up-to-date.

(3) The machine will be pre installed in the workshop before delivery.

Q

What is the warranty period for paper machines?

A

12 months after official operation

recommend products

Product Consulting

Note: Please leave your contact information and our professionals will contact you as soon as possible!