High speed automatic toilet paper/facial tissue paper rewidning and performating machine

Key words:

paper machinery

Share

Product Details

This equipment is to perforate and rewind the parent roll raw paper into various sizes of small toilet paper roll according to the requested. The finished product is neat, in good order and with equality tension.It's the best choice for new tissue paper factory.

Toilet paper rewinding machine is widely used in toilet paper shaft, non-woven fabric, air-laid paper cutting rewinding, slitting width, layer number can be adjusted according to need, quick speed, stable running, simple operation, is the paper mill or cutting and ideal facilities for the production of paper products plant.

Technical parameters-automatic toilet paper rewinding machine:

|

Model |

1092 |

1575 |

1760 |

1880 |

2400 |

2800 |

|

Parent roll width |

1350 mm |

1750 mm |

2000 mm |

2200 mm |

2350 mm |

2700 mm |

|

Parent roll diameter |

1100 mm (Others need order) |

|||||

|

Parent roll core diameter |

76.2 mm (Others need order) |

|||||

|

Control system |

PLC |

|||||

|

Embossment unit |

determined by the customer |

|||||

|

Embossment down roll |

Felt roller, paper and wool roller, rubber roller (determined by the customer) |

|||||

|

Speed |

150-180 m/min. |

|||||

|

Finished roll diameter |

90-135 mm (adjustable) |

|||||

|

Jumbo roll stand |

1-3 plies,(numbers of raw material rolls should be stated in order) |

|||||

|

Parent roll core diameter |

25-50 mm |

|||||

|

Power |

5.5-22 kw |

|||||

|

Weight |

3000-5000 |

|||||

I. Function characteristics

1, horizontal paper back rack: base paper give expulsion-typely, pneumatic belt paper, each roll of paper are independent tension adjusting device.

2, the nose structure is compact and reasonable, put high volume frame with low center, convenient operation.

3, points and tangent speed can be stepless adjustment, to adapt to the cutting and rewinding of different material, in order to achieve the highest productivity.

4, dual pressure light device, make the paper more soft

5. other related machine use in the toilet tissue paper making system

II. Processing machine of automatic rewinding tissue roll machine

the final product of toilet tissue paper making machine is toilet jubo roll, by toilet processing machine, its fianal prodct can be toilet paper, tissue paper,napkin paper,facial tissue, handkerchief paper, extraction paper and other high and low-grade daily paper.

Features of automatic toilet paper rewinding machine :

1 ,PLC (computer) control production, degree of full-automatic of production process is high, the function of machine is complete, and production efficiency is high.

2, Horizontal type unwinding stands: pneumatic wide belt to feed paper, each jumbo roll hasindependent tension adjustor and left-right adjusting device.

3, Auto stop machine function when material is used up will minimize the waste of raw material.

4, Auto edge trimming, glue spraying and sealing synchronously in one time .

5, Do not need artificial pipe putting, saves time and effort, a unique pipe putting Device to save the depository ofthe ground, immediately after the reset to complete rewinding.

6, Pneumatic adjust the tightness of winding finished products, finished products to maintain the same

7, Low cost, cover an area of an area small, it is an ideal equipment of small production of toilet paper.

toilet tissue paper processing machine include rewinding machine,cutting machine and packing machine, other napkin paer processing machine also be ok.

automatic toilet paper rewinding machine process flow :

Final product and embossing design show :

The embossing design could costom accoridng your needs .

Packaging & Shipping

| Packing | Plastic film packaging machines , loading in wooden case /lading in contatiner directly . |

| Shipping | By sea |

| Delivery time | 15-20 days after formal order ,according to your demand for automatic toilet paper rewinding machine |

Company Information

Qinyang Anshun Paper Machinery Co.,Ltd is good at Paper Making Machinery Manufacture.Professional supplier of:

1) Toilet Paper Machine (1.2m--2.8m width of parent roll, Customize Service)

2) Roll Kitchen Paper Towel Machine (1.2m--2.8m width of parent roll, Customize Service)

3) Facial Tissue Machine (2-8 output lanes)

4 )Napkin Paper machine(L-fold, 1/4-fold, 1/6-fold, 1/8-fold and other multi-fold type)

5) Hand Towel Paper Machine(C-fold, V-fold and N/Z fold type)

6) Pocket Tissue Machine(mini and standard size)

7) All kinds of Tissue Paper Cutting and Packing Machine

8) Another Household Paper Equipments and Production Line.

If you need more information about these machine,please feel free to contact me!

Welcome to contact us to get more details !

We can design the machine according to your request.

Paper making production lines we can provide:

Waste paper pulp machine production line

Automatic corrugated box production line

Corrugated paper making production line

Fluting paper pulp making production line

Coated White Board Paper production line

Honeycomb Paper making production line

testliner paper making production line

Paper plate making production line

tissue paper making production line

toilet paper making machine line

kraft paper making machine line

boxboard paper machine line

Paper coating machine line

Napkin paper machine line

OCC line

Warm Tips:

1.Before installation,you should check that equipment’s model and dimension are all right with the parts complete d and level remaining.

2.Before the debugging of installation,Checking each part is correct, lubrication supply normal.water, electricity values reaching the standard.

3.During Operation,you should pay attention to keep daily inspection, cleaning and oiling.and then examine and repair regularly.

Advantages

Customer-centered design principles

High yield, high quality

Proven skills and technical support

Thoughtful pre-sale and after-sale service

Appropriate discounts can be negotiated

Packaging, transportation and delivery

Packaging Details: According to customer's request for the price of paper recycling machine

1. Fix all moving parts with plastic film.

2. Polystyrene foam board package.

3. Wrap a few circles with tight plastic film.

4. Fix the machine on the fumigated plywood tray with iron wire.

5. Wrap it with wood and nail it.

Transportation

Mode of transport

Departure from Qingdao harbor or other ports

Delivery time

Depends on the machine or machine parts you need. But it also meets your needs

OUR SERVICES

After-sales service

(a) technical advice;

2. Project evaluation;

3. Detailed factory design;

4. Installation and testing of the entire production line;

Training of engineers and workers;

6. Provide spare parts for the entire service life at cost price within 12 months of purchase.

7. We support sending engineers to your country for the installation, commissioning and testing of the machine.

After-sales service

1. The company designs and manufactures in strict accordance with the signed equipment configuration and technical requirements, in accordance with national industry standards, and ensures that the user's equipment is a qualified product that meets the requirements.

2. After the contract comes into effect, within ten days after the equipment design and manufacturing company and the end user coordinate, link up and check the installation process; The business dealings between the two parties must be replied within 8 hours.

3. The equipment shall be installed and debugged according to the time and period agreed by both parties.

4. The quality and shelf life of the equipment are one year, and the wearing parts are not within the warranty period. Packaging quality drum shelf life of six months. Refers to the acceptance date of all goods delivered to the user as the shelf life.

5, in the quality warranty period, the company provides the necessary technical services free of charge, due to equipment design, manufacturing quality problems caused by equipment

The company will be responsible for replacement and maintenance.

6. After the shelf life, the company provides customers with lifelong technical services, and provides spare parts at preferential prices and fast delivery time for a long time.

7, the company is responsible for all production technology and installation, awarded to production workers, to ensure that the teaching workers operate.

FAQ

Q

Can we visit your factory?

A

Welcome to visit our factory. You can view our production capacity, processing capacity, inspection facilities, and operation of paper production lines. More importantly, you can directly discuss with the engineer.

Q

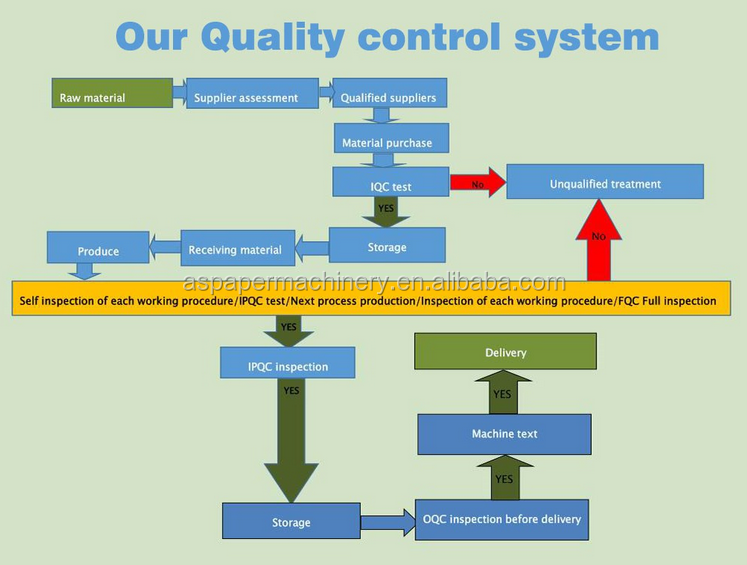

How is the quality of your equipment?

A

(1) We are a professional manufacturer of various pulp and paper machines and environmental protection equipment, with a history of more than 40 years and competitive quality.

(2) We have a technical team composed of engineers and experts. They mainly research advanced papermaking technology to ensure that our machine design is up-to-date.

(3) The machine will be pre installed in the workshop before delivery.

Q

What is the warranty period for paper machines?

A

12 months after official operation

recommend products

Product Consulting

Note: Please leave your contact information and our professionals will contact you as soon as possible!